| HOW

TO BEND WOOD

The process for

making

bent wood for furniture parts is the same as for any other kind of

bent-wood work. The pieces should be made close to the size, with

only enough material left on them for "cleaning up" after

the bending has been done. The pieces used for the bent work should

be good, clean, "live" lumber. Lumber dried on the stump

will not bend.

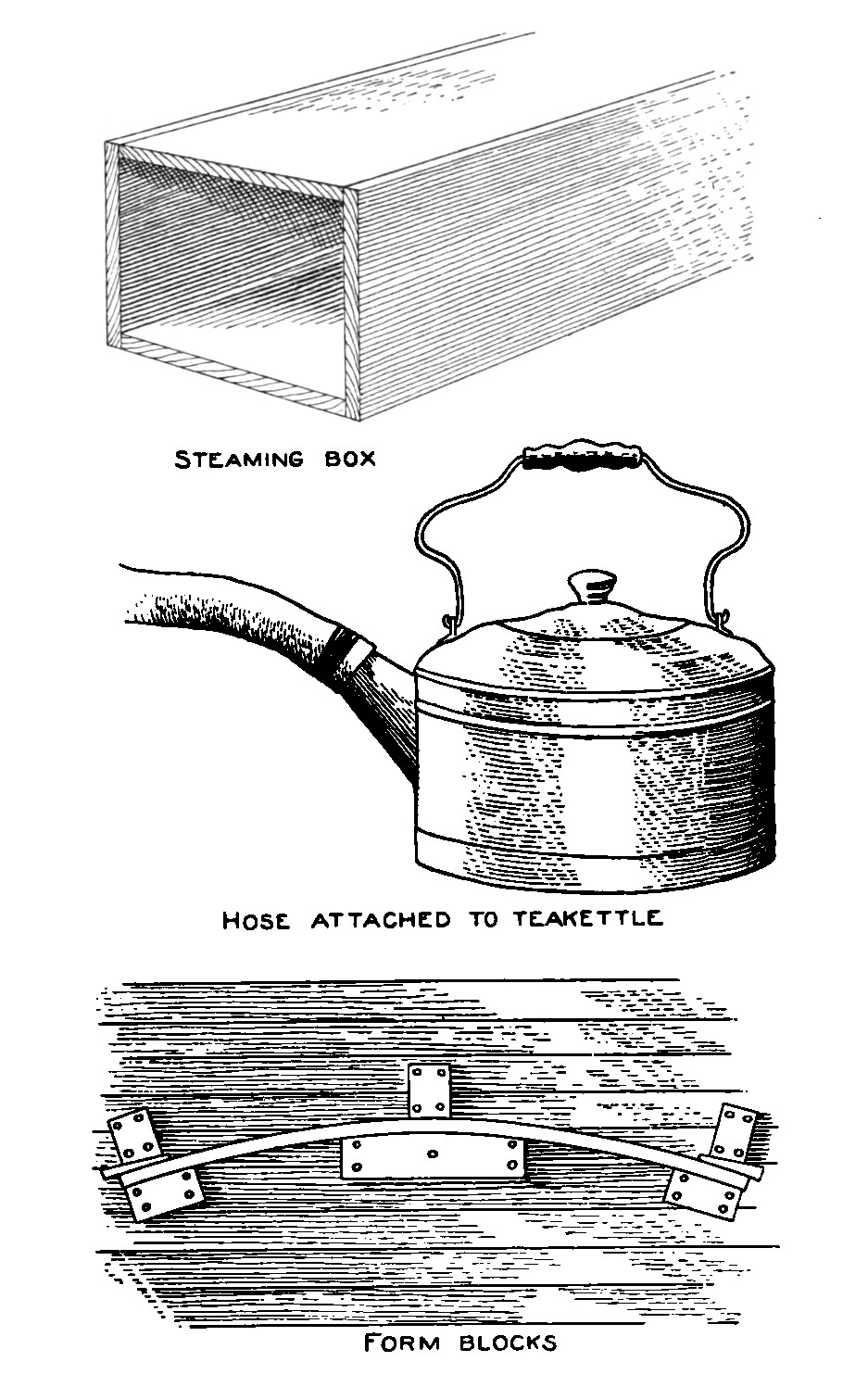

A box must be

made in

which to steam the pieces of wood to be bent. A design of a steaming

box is shown in the illustration. Such a box is made by nailing four

boards together into a square or rectangular form, the boards having

a length sufficient to take in the length of the furniture parts to

be bent. Both ends of the finished box are squared up and closed with

a board cut to the size, using felt or gunny sack in the joint to

make it as tight as possible. These ends can be nailed on, but it is

best to hold them with a bar of metal set against each one. Nailing

the ends a few times would spoil the box for further use in steaming.

A good teakettle

will

serve the purpose for a steam generator. A hose is attached to the

spout of the teakettle, as shown in the illustration, and to the

steaming box in a like manner. The steaming box should be provided

with a short piece of gas pipe turned into a hole bored into one of

the sides used for the top on which to attach the hose. A small hole

should be bored into one side of one end of the steaming box, and

this end should be arranged a trifle lower than the other end. The

hole will permit the water of condensation to escape. Steam should

not escape from the box when a charge of wood is being softened.

Steam which escapes from the box in the form of vapor has done no

work whatever, and is just so much waste of fuel. In order to give up

its heat to the wood, the steam must condense and come away from the

box as water. Therefore, in steaming a charge of pieces in the box,

never crowd the teakettle so hard that the steam escapes around the

heads of the box or through any other joints. The steam should be

supplied to the box just as fast as it condenses, and no faster. When

the pieces are placed in the box they should be so arranged that the

steam can find ready access to all sides of each piece.

The curve or

bend of the

piece to be made must be marked out on a wide board or on the floor.

Nail down several blocks of wood or pieces cut out like brackets on

the board or floor against the drawing, as shown in the illustration.

The wood is sprung between these blocks or forms after it has been

softened by steam. When taking the steamed pieces from the box do not

lose any time in securing them to the forms. Do not take out more

than one piece at a time, as it must be bent to the forms immediately

after taking it from the hot steam. The time of the steaming will

vary with the size of the pieces. Small strips may be steamed in 15

or 20 minutes, while large ones may require several hours to become

soft enough to bend. The pieces must be left in the forms until they

are thoroughly dry.

(Click for larger image) |